Description

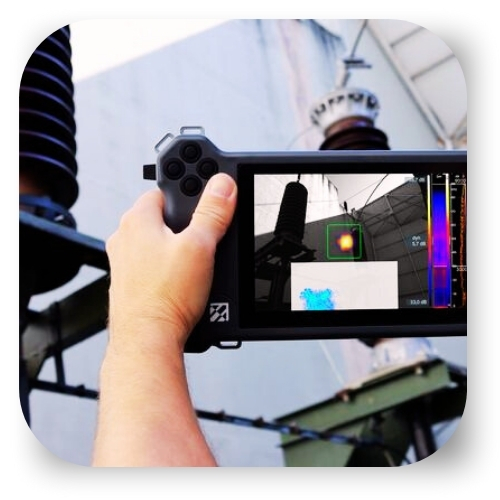

In the age of industry 4.0 the optimizing processes, increasing operational safety, and improving energy efficiency are becoming more and more significant. Meet the challenges of Maintenance 4.0 with the new SONAPHONE from SONOTEC. The digital ultrasonic testing device combines innovative sensors and software for preventive maintenance that can be operated intuitively and paves the way for new processes for new applications.

Areas of Application:

- Ultrasonic Leak Detection – Reduction of energy cost for compressed air by up to 30%

- Bearing Inspection – Recognize bearing damage early and optimize bearing lubrication

- Steam Trap & Valve Inspection – Reduce energy cost for generating steam and increase process stability

- Electrical Inspection – Detect partial discharge at an early stage and increase operational reliability

- Tightness testing – Detection of leaks & seal failures on windows, doors, cabinet, vehicles & containers

- Lubrication Monitoring – maximize performance and optimize bearing life with precision ultrasound assisted greasing

Broadband Ultrasonic analysis: Frequency range from 20 to 100 kHz

Software that is intuitive to operate

- Apps accompany you through the entire testing process; from planning, testing and documentation to analysis

- SONAPHONE can be operated intuitively like a tablet via 5-inch display with multi-touchscreen

- Reduce Paper records, which are error-prone and above all time-consuming